Service Operating Models of the Future

The rise of trends such as remote-first, industrial IOT-powered components, and advanced service offerings are changing the way services generate revenue. Explore how to adapt your strategy.

Discover the Solution →

🔍 A Real-World Story from South America

How a large mining equipment manufacturer discovered the gap between predictive maintenance alerts and actual revenue generation.

They had tagged most of their mining machines with IoT sensors to capture real-time condition data. They had an entire Condition Monitoring Team analyzing the alerts. But there was one big problem:

Too Many Alerts, No Real Action

The CIO's Challenge: Find a Solution

The CIO approached me and asked,

I spent weeks studying their process and working with the team. The company decided to build a workaround:

- They integrated ERP, CRM on the cloud and a pricing application

- They built interfaces to transfer alerts from one system to another

🚨 But it didn't solve the real problem:

- It still required manual work—someone had to key in values manually

- The process was disorganized—alerts were transferred, but monetization was still an afterthought

- The company spent a fortune on interfaces that just moved alerts from one place to another, without creating real value

At the end of the project, the company had a system, but not the right solution. They still weren't making money from their predictive maintenance alerts.

The Alert Problem

The system generated hundreds of alerts every day. These alerts were:

- Sent to the sales team as maintenance recommendations

- Forwarded to customers as service advisories

But instead of leading to business value, something strange kept happening:

- The sales team and customers ignored most alerts.

- Many alerts were useless, with no actionable follow-up.

- The emails containing alerts were either deleted or left unread.

This was a massive gap—the company was investing heavily in predictive maintenance but had no way to monetize it.

The Big Idea: Automating the Entire Process

Predictive maintenance is NOT just about sending alerts. It's about creating a revenue loop.

That's why we built a unified system that does this automatically

That's why we built a unified system that does this automatically:

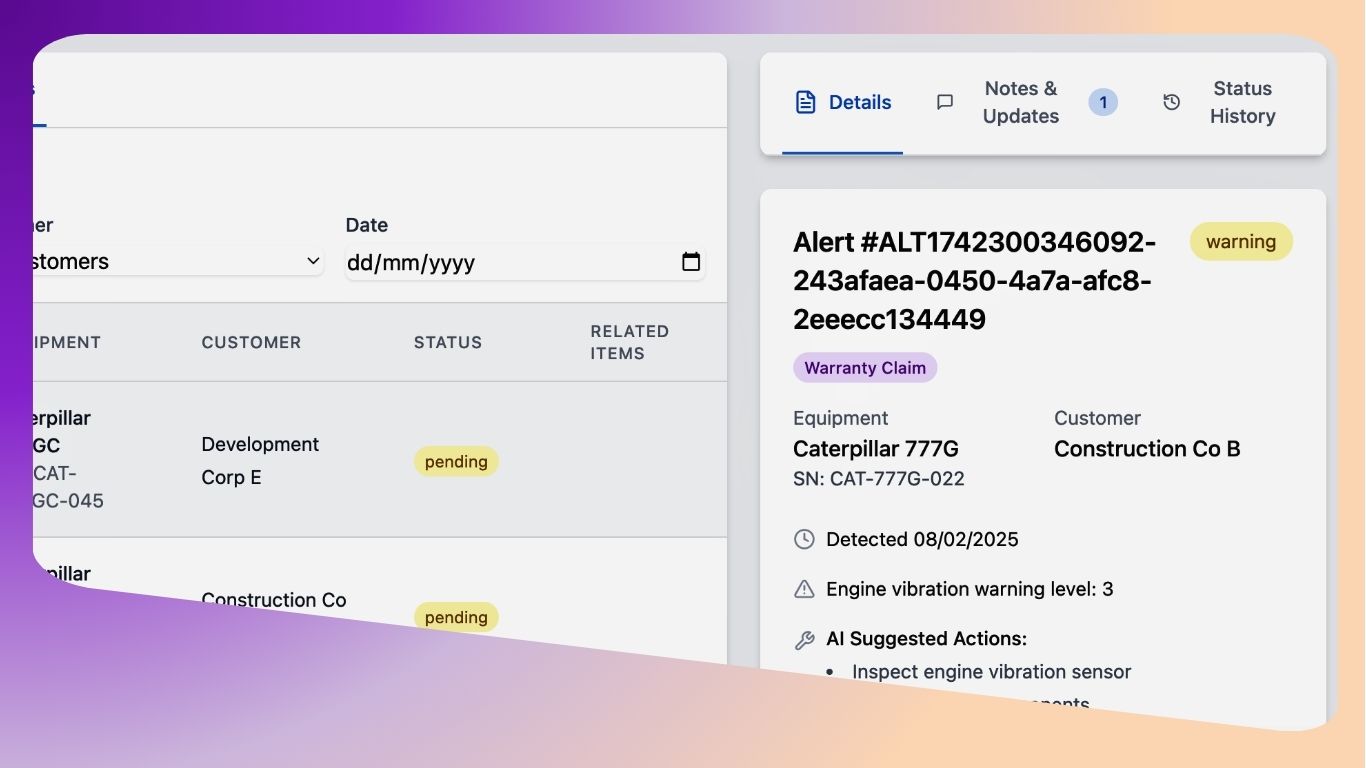

🔄 Ingests alerts from sensors & IoT platforms

Seamlessly connects with your existing IoT infrastructure and sensor networks

🤖 Filters false alerts using AI

Advanced AI algorithms eliminate noise and focus on actionable insights

⚡ Automatically converts valid alerts into:

Transforms raw data into business opportunities

- Warranty claims (if under warranty)

- Service contract inclusions (if covered)

- Corrective maintenance work orders (if needed)

- Quote generation for non-covered repairs

- Pre-cost estimation before sending proposals to customers

💡 Instead of spending millions on disconnected systems, our platform seamlessly connects the entire ecosystem—from predictive maintenance to actual revenue generation.

The Future of Predictive Maintenance Monetization

❌ Many companies are still stuck in the same old loop:

- Too many alerts

- No structured workflow

- No revenue impact

✅ With our system, manufacturers can:

Directly convert alerts into business opportunities, increasing service revenue, customer satisfaction, and operational efficiency.

Ready to Transform Your Predictive Maintenance?

Stop losing revenue from ignored alerts. Start converting your IoT data into real business value with our automated service operating model.